How Regular Welding Inspection Madison Can Conserve You Money And Time

How Regular Welding Inspection Madison Can Conserve You Money And Time

Blog Article

Recognizing the Principles of Welding Assessment to Make Sure Quality and Security

In the world of modern-day engineering, welding assessment stands as a keystone for making certain both the top quality and safety and security of structural developments. The process includes a careful analysis of welded joints, using innovative methods such as ultrasonic and radiographic screening to find surprise imperfections. The experience of certified examiners is essential, as they connect the space between theoretical standards and practical application. Their duty expands beyond plain discovery, including the documentation and interaction of searchings for to relevant stakeholders. What are the nuances of these assessment methods that make them vital for maintaining structural integrity?

Significance of Welding Examination

In the world of industrial manufacture, the importance of welding examination can not be overemphasized. Welding inspection plays an important role in making sure the integrity, security, and longevity of welded structures. Given the varied applications of welding in sectors such as building and construction, auto, aerospace, and shipbuilding, the demand for rigid high quality control steps is paramount. Proper evaluation ensures that welds fulfill defined standards and codes, which is necessary for avoiding architectural failures that could lead to devastating repercussions.

The procedure of welding naturally involves intricate variables, consisting of temperature level, product buildings, and environmental problems, every one of which can influence the quality of the weld. A comprehensive assessment determines defects such as cracks, porosity, and insufficient blend, which can endanger the stamina and integrity of the weld. By identifying these problems early, rehabilitative actions can be taken, thereby decreasing the danger of failure and linked prices.

In addition, welding examination contributes to governing conformity, as numerous sectors are governed by rigorous security standards and standards. Failing to adhere to these laws can cause monetary charges and legal obligations. Inevitably, welding evaluation not just safeguards physical frameworks however also shields human lives and supports industry online reputations.

Secret Welding Evaluation Techniques

Although welding examination is critical to making sure the quality and safety and security of bonded frameworks, it is the details techniques employed that figure out the performance of the examination procedure. Key welding evaluation methods can be broadly classified into non-destructive testing (NDT) and damaging testing.

Ultrasonic and radiographic screening are advanced strategies that permit inspectors to evaluate the inner integrity of the weld. Ultrasonic screening uses high-frequency acoustic waves to discover suspensions, while radiographic testing utilizes X-rays or gamma rays to create a photo of the weld's inside. Magnetic bit screening and fluid penetrant screening are surface area inspection techniques made use of to situate surface and near-surface flaws. On the other hand, damaging testing approaches involve physically reducing the weld or breaking to examine its mechanical buildings. These thorough assessment techniques guarantee that welds meet industry criteria and security requirements, thus guaranteeing architectural honesty and performance.

Role of Licensed Assessors

Licensed inspectors play a pivotal role in the welding assessment procedure, guaranteeing that all welds comply with stringent market standards and safety and security laws. Their expertise is vital in recognizing problems or irregularities that might endanger the architectural stability of a weld. By thoroughly taking a look at each weld, certified examiners assist stop prospective failings that could cause costly repair services or harmful accidents.

To end up click here to read being certified, assessors have to go through rigorous training and screening, which familiarizes them with numerous welding techniques, products, and screening approaches. This detailed expertise enables them to review weld quality effectively and make educated judgments about their safety and security and integrity. In addition, certified inspectors excel in translating blueprints and requirements, ensuring that the welding job straightens with the job's style needs.

An indispensable part of their function is to document their findings thoroughly, supplying a detailed document of the evaluation procedure. This documentation is vital for traceability and accountability, working as a main record of conformity with industry criteria. Qualified assessors likewise play a vital duty in facilitating interaction in between job stakeholders, providing suggestions and understandings to enhance welding practices and outcomes. Their payment is vital in maintaining high degrees of high quality and security in welding operations.

Tools Made Use Of in Welding Examination

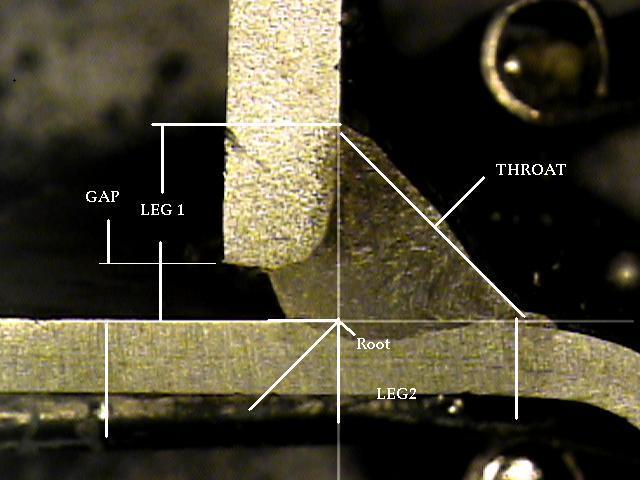

Welding inspectors rely upon a selection of specialized tools to execute their responsibilities efficiently, guaranteeing each weld meets the necessary standards. Among these devices, visual inspection aids like amplifying glasses and mirrors are basic, enabling examiners to closely check out welds for surface defects such as splits, porosity, and undercut. Calipers and fillet weld gauges are crucial for determining weld measurements to verify compliance with design specs.

Advanced tools prolong past aesthetic help, including non-destructive testing (NDT) equipment. Ultrasonic testing tools are essential in spotting subsurface problems, using audio waves to reveal interior discontinuities without compromising the weld's integrity. Radiographic screening additional reading utilizes X-rays or gamma rays to capture pictures of a weld's inside, highlighting potential issues.

Magnetic particle screening is an additional essential tool, particularly for discovering surface and near-surface suspensions in ferromagnetic materials. By using ferrous fragments and magnetic fields, assessors can identify defects that may otherwise be unnoticeable.

Dye penetrant assessment is commonly utilized for non-ferrous products, giving a contrast-enhanced visual look for surface-breaking defects. Welding Inspection Madison. With each other, these tools make it possible for welding assessors to comprehensively evaluate weld top quality, guaranteeing safety and reliability in numerous applications throughout sectors

Ensuring Structural Honesty

Welding treatments must stick to well established requirements and codes, such as those specified by the American Welding Culture (AWS) or the International Organization for Standardization (ISO) These standards make sure that the welds can stand up to ecological aspects and operational anxieties. Certified and certified welders play an essential role in this process, as their competence makes certain that strategies are used properly, decreasing defects such as splits, porosity, and insufficient blend.

Post-weld inspection is one more crucial element of verifying architectural honesty. These examinations confirm that the welds fulfill the called for top quality standards, providing assurance of their durability and reliability.

Conclusion

The fundamentals of welding examination are important for preserving the top quality and safety of bonded structures. The usage of specialized tools additionally boosts the evaluation procedure, inevitably safeguarding human lives and prolonging the life expectancy of welded building and constructions.

Welding examination plays an essential role in ensuring the integrity, safety, and longevity of bonded frameworks.Although welding evaluation is crucial to making sure the quality and safety of browse around these guys welded frameworks, it is the particular techniques employed that determine the effectiveness of the inspection procedure. Trick welding assessment techniques can be broadly categorized into non-destructive testing (NDT) and harmful screening.Certified examiners play an essential role in the welding assessment process, ensuring that all welds conform with rigid industry criteria and safety regulations.The principles of welding examination are vital for maintaining the top quality and security of welded frameworks.

Report this page